Unique, "EB on Breast"

Unique, "EB on Breast"

1787 Brasher Doubloon from

The Gold Rush Collection

|

"Barnacles of Gold" - The Story of Dahlonega's Famed Findley Mine

By Anne Dismukes Amerson

The Findley Gold Mine was one of Dahlonega’s most famous and

productive mines for almost a century. Opened shortly before the Civil War

and abandoned soon after the United States entered World War II,

the mine site was largely forgotten over the years except by history

buffs and gold mining enthusiasts.

Discovery of the Famed Findley Chute

The

earliest information about the Findley Chute (alternately spelled

“Shute” and “Shoot” and referring to a rich

vein) comes from a mining pamphlet published August 1, 1875, by

W. Reese Crisson, who owned the property at the time. In it, Crisson

states that “the celebrated Findley vein....was discovered

in 1858 by a man by the name of Duncan, who was employed by Col.

J. J. Findley to test for gold, and while thus employed found this

rich vein.”

Crisson

went on to explain that Findley had gone into partnership with local

entrepreneur Harrison W. Riley and the two of them had worked the

mine to a depth of 160 feet. At that point, they struck a vein of

water, which poured into their shaft and forced them out.

Crisson

also gave an eyewitness account of seeing Findley hand-mortar a

gallon bucket of ore taken from one of the mine’s pockets.

When he had removed the rock, a half-gallon of pure gold was

left.

An

interesting story about Duncan was related by W. R. Crisson’s

son, E. E. Crisson to Andrew W. Cain, who includes it in the section

on the Findley Chute in his

History of Lumpkin County

for the First Hundred Years 1832-1932

. According to

the story, Duncan claimed he was part Indian and said he could dream

where to find gold. It was supposedly in such a dream that he saw

an incredibly rich vein of solid gold and knew where to dig to find

it.

The Beginning of Vein Mining

Prior

to Duncan’s discovery, vein mining was still relatively new

in the area. Gold had been discovered near the Chestatee River in

1828, but the miners who flocked to north Georgia hoping to strike

it rich panned the streambeds using placer mining tools and

techniques,

including pans, sluice boxes, and rockers. They did not initially

realize that the loose particles of gold did not originate in the

streams but had washed down from the hills by the forces of erosion.

It was not until the “easy gold” had been found that

men turned their sights and their shovels into the hillsides in

their quest for the precious metal.

Prior

to Duncan’s discovery, vein mining was still relatively new

in the area. Gold had been discovered near the Chestatee River in

1828, but the miners who flocked to north Georgia hoping to strike

it rich panned the streambeds using placer mining tools and

techniques,

including pans, sluice boxes, and rockers. They did not initially

realize that the loose particles of gold did not originate in the

streams but had washed down from the hills by the forces of erosion.

It was not until the “easy gold” had been found that

men turned their sights and their shovels into the hillsides in

their quest for the precious metal.

Ownership of the Findley Property

The

history of ownership of Land Lot 1,048, on which almost all the

Findley mining operations took place, is complex, for it was divided

into half- and quarter-lots, all of which changed hands more often

than pieces of property on a Monopoly game board. Disagreements

about ownership followed by law suits were common. Information about

the numerous owners is available, but this article will focus only

on those who made significant developments to the property.

The

lot was originally granted by the State to Talbot Davison, of Jones

County, in the Cherokee land lottery of 1833. Although there were

several owners in the years between 1833 and 1852, apparently the

first person to make any use of the land was Charles M. McJunkin,

a woodcutter. After having cut the timber on the property, he sold

his half of the lot to James Jefferson Findley in February of 1858.

At that time the lot was considered an “old horse” that

had seen better days.

Soon

after the purchase, Findley secured the services of Charles Duncan,

who was reputed to be one of the best prospectors in the area to

prospect his newly acquired lot for gold. As described above by

W. R. Crisson, Duncan soon found a small but remarkably rich vein

which has become famous in the annals of Lumpkin County gold mining

history as “The Findley Chute.”

Findley

and his partner, Harrison W. Riley, worked the chute for three or

four months and excavated a 4 by 6 foot incline shaft

“sufficiently

large to permit three men to work at the same time.” The rich

yields from the mine were reportedly carried to the Dahlonega Mint

in a bucket after dark to avoid attracting attention. Findley’s

and Riley’s operations came to an abrupt halt when water filled

the shaft to a depth of 8-10 feet.

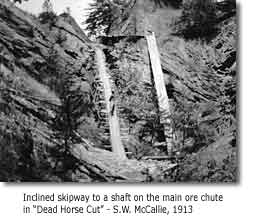

Attempts to Recover the Lost Chute

Subsequently,

the Findley property was sold to the Stephenson Gold Mining Company

in 1863. Dr. M. F. Stephenson (assayer at the Dahlonega Branch Mint

1850-1853) sunk a 100-foot shaft at the top of the hill north of

the chute. He then cut a tunnel from the bottom of the new shaft

that was designed to strike the chute from that angle. His operations

were halted by the scarcity of labor and the high price of powder

for blasting the rock. Later operations proved that his tunnel stopped

only five or six feet from the chute.

The Dahlonega Mining Company purchased the Findley property in 1866

but did little work on the mine aside from running a long tunnel

designed, like Singleton’s, to strike the chute at the bottom

of the incline (a distance of about 500 feet). After driving 300

feet, Superintendent Amory Dexter halted work after workers hit

a belt of very hard rock. His decision was also influenced by a

title dispute.

In 1868, the Dahlonega Mining Company leased the Findley and Lockhart

mines to local miners Crisson and Huff. In 1871, W. R. Crisson (Huff

having retired by this time) moved the Lockhart’s 24-stamp

mill to the Findley and began mining operations on that property

after replacing the badly worn stamps with new ones.

In 1875, N. H. Hand (General Manager for the Dahlonega Mining Company)

began to develop the property in order to place it on the market.

Frank W. Hall was put in charge of the work. He drove a tunnel from

the Dexter tunnel to the bottom of the Stephenson shaft and successfully

continued the Stephenson tunnel to the elusive chute. Hall reported

taking out “about $3,000 in handsome free gold specimens and

that a great deal more was left in place, the object of the work

being to develop the mine for sale.”

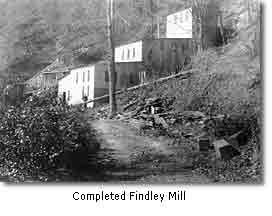

It

was during this time that “the Little Findley Mill”

was erected on the northwest side of the ridge to mill the ore brought

by flume from the large cut on top of the ridge started by W. R.

Crisson. This mill was the 10-stamp Hall mill moved from the Lawrence

Mine (located on the Mustering Ground near the Dahlonega Public

Square) and was run by steam.

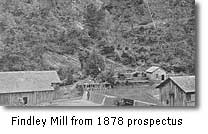

Findley Ridge, Backbone of the Georgia Gold Belt

In

1878, the Findley Gold Mining Company of New York City purchased

the property for $30,000. According to a prospectus published by

the company that year, the Findley lot “is conceded by every

one to contain the largest mass of gold-bearing ores in the Southern

belt.” Findley Ridge, called the “backbone” of

the Georgia gold belt by mining engineers and geologists, was dramatically

described as “a precipitous ridge, jutting into the valley,

with almost sheer ascent of 500 feet above the level of the river.”

The celebrated Findley Vein was described in the prospectus as “a

clear, lively quartz lode about three feet thick, carrying a remarkably

rich ‘pay streak’ of two to eight inches, and yielding

in many places almost pure masses of gold.” It went on to

note that “nuggets weighing from twenty to fifty pennyweights,

are sometimes broken from the quartz while taking down the vein”and

“one mass of quartz and gold taken from this lode, weighing

about twelve pounds, produced nearly eight pounds of gold.”

The

Findley Gold Mining Company enlarged the “Little Findley Mill”

to 20 stamps and increased its steam power. It also replaced the

24-stamp mill beside Yahoola Creek with 40 stamps and installed

steam pumps to raise water from the Findley Ditch 175 feet to the

top of the ridge for use in working the upper cut.

The

Findley Gold Mining Company enlarged the “Little Findley Mill”

to 20 stamps and increased its steam power. It also replaced the

24-stamp mill beside Yahoola Creek with 40 stamps and installed

steam pumps to raise water from the Findley Ditch 175 feet to the

top of the ridge for use in working the upper cut.

This

information is confirmed by an item in the September 8, 1876, issue

of Dahlonega’s newspaper, The Mountain Signal: “A ram

of the largest size is throwing water into a reservoir on the summit

of the hill 153 feet above the ditch....”

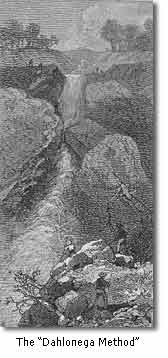

The Dahlonega Method

A

reservoir was dug at the top of the ridge to store the water, which

was released at the end of the day to wash the ore from the cuts

down to the mill. This method was apparently developed locally and

came to be known as “the Dahlonega Method.”

A

reservoir was dug at the top of the ridge to store the water, which

was released at the end of the day to wash the ore from the cuts

down to the mill. This method was apparently developed locally and

came to be known as “the Dahlonega Method.”

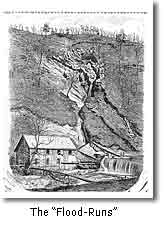

That

process was colorfully described by a writer sent to Dahlonega in

1879 by

Harper’s New Monthly Magazine

to research and write an article on “Gold Mining in Georgia.”

The article which appeared in the September 1879 issue provides

wonderful eyewitness descriptions of scenes long vanished in time,

such as “the ruins of the old United States Mint, looking

very romantic in the sunset glow.” Many of them are illustrated

with fine pen-and-ink drawings, including a dramatic scene showing

great torrents of water sweeping ore down the hillside to be processed

in the mill below.

“This

operation is called ‘flooding’ the mine, and one evening

we rode out to the Findley Mine to see it,” wrote the unnamed

author. “There the cut runs straight up and down the side

of a hill 500 feet high, and is in the form of a deep, irregular,

vertical trench.....We climbed to the summit of a high knoll jutting

up by the line of the cut, and waited. In a moment an ominous ‘grumble

and rumble and roar’ was heard, which, beginning faint and

far aloft, gradually grew more threatening, until there was a sudden

volley of sound, and at the end of the narrow trench a mighty mass

of red-brown waters came leaping over the ledge....But it was not

all water, nor even mud. Tons upon tons of broken rocks were coming

down through this terrible flume, rolling over and over, rattling

among their fellows, grinding along the walls, bounding out of the

narrow crevice, leaping high above the red spray, and falling in

ringing rain upon the stony floor. The noise was a hoarse, crushing,

terrific roar. The force was prodigious.”

The dimensions of the reservoir on Findley Ridge were given by State Geologist W. S. Yeates in his

Preliminary Report on a part of the Gold Deposits of Georgia

published in

1896. It was “150 feet long, 15 feet wide, and 6 feet deep,

from which water is delivered, by ditches and iron pipes, to various

parts of the open cuts, for making the flood-runs of saprolite from

the cuts to the mill, and for operating the hydraulic giants.”

The dimensions of the reservoir on Findley Ridge were given by State Geologist W. S. Yeates in his

Preliminary Report on a part of the Gold Deposits of Georgia

published in

1896. It was “150 feet long, 15 feet wide, and 6 feet deep,

from which water is delivered, by ditches and iron pipes, to various

parts of the open cuts, for making the flood-runs of saprolite from

the cuts to the mill, and for operating the hydraulic giants.”

Despite

the glowing description of the Findley property and its potential

described in its prospectus, the Findley Gold Mining Company apparently

did not prosper. According to Yeates, this company made the error

of sending a young relative of a stockholder, fresh out of mining

school, to be superintendent of the mine. He was unwilling to take

suggestions from experienced local miners and was unable to find

the famed chute, which had been lost. After some work in the open

cuts, the operation came to a halt after a couple of years.

The Findley Chute: Lost - Found - Lost Again

In

1880, R. B. King leased the property. He located the Findley Chute

almost immediately and mined it with great success. Just before

his year’s lease expired, he “lost” the Chute

intentionally! He reportedly made enough from the vein in twelve

months to start a bank in Denver, Colorado.

The

Findley Gold Mining Company continued to own but not work the Findley

property until it was sold at sheriff’s sale in 1885. In 1890,

it was purchased by the Trefoil Gold Mining Company of St. Louis,

Missouri. This company repaired the mill and put in a set of concentrators,

which proved a fruitless expense.

At

the time of State Geologist Yeates’ visit to the Findley Mine

in 1895, the property was owned by Christian Wahl, of Milwaukee,

Wisconsin, and managed by Capt. H. D. Ingersoll. Yeates noted that

“while no extensive work seems to have been done, yet the

work on it has been constant;.....and the property is one of the

best developed in the county.”

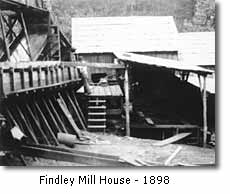

Yeates

described the mill house as containing 40 stamps, each weighing

450 pounds, 20 of which were “practically new.” “When

last rebuilt,” Yeates wrote, “the mill-house was planned,

so as to admit of the introduction of a concentrating plant, for

handling the sulphide ores.”

Yeates

described the mill house as containing 40 stamps, each weighing

450 pounds, 20 of which were “practically new.” “When

last rebuilt,” Yeates wrote, “the mill-house was planned,

so as to admit of the introduction of a concentrating plant, for

handling the sulphide ores.”

The

mill was driven by water contained behind a 17-foot-high dam across

Yahoola Creek. A 32-inch Leffel turbine wheel furnished 60 H. P.

The large pump in the pump house had been installed in 1895 by the

current owner of the property, C. Wahl, and was used to pump water

to the reservoir on top of the ridge. The water was taken from the

Findley ditch, which ran about halfway up the ridge.

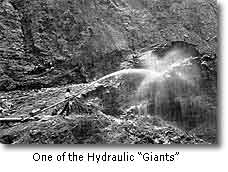

Note: This

was one of numerous adueducts which conveyed water

from higher elevations with enough pressure to operate

hydraulic cannons. What was a slow and laborious

process for a man with a pick and shovel was

accomplished in a mere fraction of the time by a great

jet of water tearing away the earth with as much

pressure as 135 lbs. per square inch. It was common

to estimate the work of a water cannon as equal to the

labor of ten men.

Note: This

was one of numerous adueducts which conveyed water

from higher elevations with enough pressure to operate

hydraulic cannons. What was a slow and laborious

process for a man with a pick and shovel was

accomplished in a mere fraction of the time by a great

jet of water tearing away the earth with as much

pressure as 135 lbs. per square inch. It was common

to estimate the work of a water cannon as equal to the

labor of ten men.

A booklet

entitled, "Announcement of the Dahlonega Consolidated Gold

Mining Company" of Dahlonega, Georgia, published in 1899, described

the Findley Mine and Mill as “unquestionably one of the most

desirable properties in the South.” It went on to say, “The

high, steep hill, rising abruptly above the mill, has always been

considered as the heart of the Georgia gold belt. On the hill is

situated the celebrated “Findley Shute,’ a wonderfully

prolific pocket vein from which alone at least $2000,000.00 have

been taken out and which does not appear to be exhausted.”

The

booklet continued with a glowing detailed description of the property,

noting the “40-stamp mill in excellent repair, and another

piece of machinery which is a novelty....a pump....which is the

only machine of its kind in existence, a Duplex water motor, made

by Filer & Stowell, of Milwaukee. It operates, from the canal

water, under a head of 283 feet and lifts 176,000 cubic feet of

water to the vertical height of 435 feet daily.”

“Barnacles of Gold”

An article appeared in the April 27, 1901,

Atlanta Journal

Dahlonega, the Center

of Yellow Metal Enterprises” and “Excitement Over the

Rediscovery of a Long Lost Mine.”

After

describing how the “dull, sleepy town of four years ago”

had been transformed into a “busy, bustling little city”

as a result of the magnitude of the developments (including electric

lights) made by the Consolidated Mining Company, McNelley told of

“the latest and by far the richest discovery ever made in

the mines here.” He went on to relate the history of the Findley

Chute and tell how “two practical miners of this place”

named Witt & Campbell had set out with determination to locate

the “long-lost treasure.”

Campbell

got discouraged and quit, and Witt was almost at the point of giving

it up as a fruitless search when he instructed his workmen to put

in “one more shot.” If that didn’t break into

the gold, they were to “pull out their tools and give it up

as a bad job.” The hole was drilled, the dynamite put in,

the fuse ignited, and the men hurried out of the hole. After the

explosion when the smoke had cleared, the miners went back inside

“with bated breath to discover the result.” There, to

their astonishment, they saw “exposed to the naked eye an

almost solid mass of gold nuggets sticking out like warts on the

face of the quartz.” They had struck the famed Findley Chute!

According

to McNelley, the discovery had taken place “about two weeks

ago.” “Captain” Witt had kept his men constantly

working to extract the ore and had already mined 326 pounds of the

rich ore. He was obviously eager to get as much gold as possible

before his lease expired on June 1, at which time the property would

be taken over by the Consolidated Company.

The

Journal

correspondent described the “chute

or ore in the mine as zig-zag in shape” with”cones”

projecting right and left, each weighted down with “barnacles

of pure gold.” He wrote enthusiastically, “The seams

in the rock are full of nuggets and in many cases the quartz is

held together with pure gold.” He quoted an old miner as saying,

“The Findley is a-goin’ to run to Chiney, and the deeper

you git on the vein, the better and richer it will be.”

According

to McNelly, the Chute was excavated to “about 350 feet”

at the time. He noted that Consolidated Company planned to “drive

a tunnel in at the base of the hill and intersect the chute some

hundred feet below” in order to work the entire vein.

The

Consolidated Company also proposed to increase the number of stamps

on the Findley property from 40 to 100 to give it a 200-ton capacity.

At an estimated average value of $3 per ton of ore, the expanded

Findley was expected to earn $600 per day. However, the company’s

grandiose dreams never came to fruition, and it was bankrupt by

1906. Some mining probably took place on the property in subsequent

years but on a minor scale.

The

Consolidated Company also proposed to increase the number of stamps

on the Findley property from 40 to 100 to give it a 200-ton capacity.

At an estimated average value of $3 per ton of ore, the expanded

Findley was expected to earn $600 per day. However, the company’s

grandiose dreams never came to fruition, and it was bankrupt by

1906. Some mining probably took place on the property in subsequent

years but on a minor scale.

Mining at the Findley in the 1920s and 30s

Major

Graham Dugas is usually associated with the Calhoun Mine, where

he made a big strike in the 1940s and made national news. However,

two old photographs show him with miners at the Findley Mine in

the late 1920s. The extent of his involvement there is not known.

Major

Graham Dugas is usually associated with the Calhoun Mine, where

he made a big strike in the 1940s and made national news. However,

two old photographs show him with miners at the Findley Mine in

the late 1920s. The extent of his involvement there is not known.

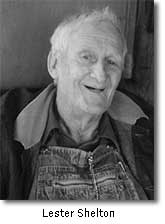

A decade

later, Cornelius O’Kane erected a new mill on the Findley

property beside Yahoola Creek. Lester Shelton worked for O’Kane

at the time and helped clear out the area around the old mine so

the new stamp mill could be built. He hauled sand from a sandbar

on the other side of Yahoola Creek to put in the cement of the foundation.

“There

wasn’t much of a road to the Findley at that time, so I helped

work on it with a drag-pan and mule,” he related to this author

in a 1993 interview. “It was real narrow because there wasn’t

much room between Yahoola Creek and the bluffs of Crown Mountain.

When the owners bought a diesel engine to run the mill, nobody thought

they could get it in on that road except for Tal Odum, who said

he would do it.

“There

wasn’t much of a road to the Findley at that time, so I helped

work on it with a drag-pan and mule,” he related to this author

in a 1993 interview. “It was real narrow because there wasn’t

much room between Yahoola Creek and the bluffs of Crown Mountain.

When the owners bought a diesel engine to run the mill, nobody thought

they could get it in on that road except for Tal Odum, who said

he would do it.

“Tal

was behind the wheel, and I was standing in the back of his old

Chevrolet truck holding on to the engine to keep it from shifting,

when the vehicle started to tilt sideways. The weight of the engine

was making the tires on one side sink deep into the soft dirt. I

jumped off just as the truck started to turn over. I yelled at Tal,

but he was already jumping free. We watched helplessly as the truck

turned bottom-side up in the middle of the Yahoola!”

Paul

Early helped move the 10-stamp “Little Findley” mill

from up on Findley Ridge down to the new mill. Other heavy equipment

was moved to the Findley from the Mary Henry gold mine. According

to Early, a tunnel was dug into the base of Findley Ridge with the

intention of striking the historic Findley Chute, but the ore dug

out of the tunnel proved to be of a disappointingly low grade.

Playing “Goldball”

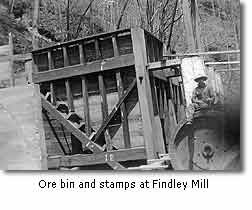

Ross

Adams also worked at the Lockhart and Findley Mines when they were

owned by “Ol’ Man O’Kane.” “My job

was usually shoveling ore with a square-bottomed shovel to feed

the stamps that pounded it into fine dust, but the Findley was a

self-feeder with a hopper that fed ore directly to the stamp mill,”

he related in a 1993 interview with this author. “The crushed

ore went into a sluice box to be washed. The gold was heavier and

fell to the bottom, where it was caught on copper plates coated

with quicksilver.

Ross

Adams also worked at the Lockhart and Findley Mines when they were

owned by “Ol’ Man O’Kane.” “My job

was usually shoveling ore with a square-bottomed shovel to feed

the stamps that pounded it into fine dust, but the Findley was a

self-feeder with a hopper that fed ore directly to the stamp mill,”

he related in a 1993 interview with this author. “The crushed

ore went into a sluice box to be washed. The gold was heavier and

fell to the bottom, where it was caught on copper plates coated

with quicksilver.

“Every

week or so we would have what was called a ‘cleanup’

to get the gold. First, the mercury plates were scraped with a piece

of hard rubber. Then the mass of gold and quicksilver was put into

a round iron container and heated in the blacksmith’s forge.

The heat made the quicksilver boil out and caused the gold to melt

and run together so that it came out looking like a half a pound

of yellow butter. Sometimes it would weigh six or seven pounds,

and I remember throwing a good-sized ball of gold back and forth

with another fellow like we were pitching a baseball.

“I

also drilled with a jackhammer inside the mines and set off dynamite

to blast out the rock. There was always a bell set up on the hill

that was rung to let everybody know there was dynamite in the hole

fixin’ to blow. One time I just barely got out in time, and

the blast liked to have knocked me down!”

O’Kane’s

new Findley Mill began operations in the summer of 1940 but only

operated a couple of years before World War II put a halt to mining.

Men were drafted, and dynamite was unavailable. A college student

named Hinton Amerson exploring the mill in 1953 found a newspaper

dated 1942, suggesting that the mine was still operating at that

time.

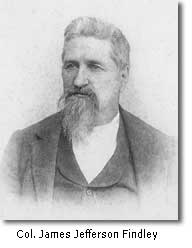

Col. James Jefferson Findley

No

history of the Findley Mine would be complete without some information

about the man whose name has come down in history because of its

association with the mining property and the knob of Crown Mountain

still known today as “Findley Ridge.” Since Findley

didn’t purchase the property until 1858, the ridge may not

have had a name when Dr. Matthew F. Stephenson made his famous speech

from the porch of the Lumpkin County Courthouse attempting to dissuade

local miners from leaving to join the 1849 California Gold Rush.

No

history of the Findley Mine would be complete without some information

about the man whose name has come down in history because of its

association with the mining property and the knob of Crown Mountain

still known today as “Findley Ridge.” Since Findley

didn’t purchase the property until 1858, the ridge may not

have had a name when Dr. Matthew F. Stephenson made his famous speech

from the porch of the Lumpkin County Courthouse attempting to dissuade

local miners from leaving to join the 1849 California Gold Rush.

“Why

go to California?” he asked them, pointing dramatically toward

the small mountain about a half-mile south of the Dahlonega Public

Square. “In that ridge lies more gold than man ever dreamt

of. There’s millions in it!” The miners who disregarded

his words and headed West nevertheless quoted the expression until

"There's millions in it" became a popular idiom. Mark

Twain further immortalized the phrase by using it in his book, "The

Gilded Age."

James

Jefferson Findley was born in 1829 and reportedly came to Dahlonega

at a young age. A lawyer by profession, he was elected sheriff of

Lumpkin County and later represented the county in the Georgia Legislature.

During

the Civil War, Findley was a Major in Company D, 52nd Georgia Regiment,

C.S.A. (“Boyd Guards”) and afterwards a Colonel who

commanded the Lumpkin County Home Guards. He had his headquarters

in the 1836 courthouse, which also served as a jail for deserters,

bushwhackers, and other military prisoners. In October of 1864,

he was the officer in charge who ordered the execution of three

Union soldiers, whom he believed to be bushwhackers who had been

burning and looting in the area. A month later, Col. Findley and

his 1st Georgia State Cavalry Home Guards followed raiding Union

troops over the top of Amicalola Mountain and captured them after

a skirmish that took place in Bucktown in Gilmer County.

J.

J. Findley had three sons by his first wife, Elizabeth Stephens

(1825-1879). He married Martha Mathilda Williams (1848-1931) of

Dahlonega in 1886. Their only child, Jefferson William Findley,

was born in 1887, but Findley did not live to see this son grow

up. He died of cancer in 1888. In his obituary published in the

March 9, 1888

Dahlonega Signal

, he was

described as “true to principle, true to friends, a genial,

wholesome, liberal, gentleman” who always “wore a cheerful

smile.”

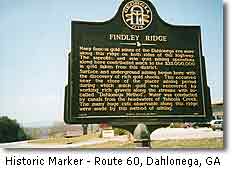

The Findley Ridge Roadside Park and Historical Marker

In

1961, a roadside park was created beside Highway 60 where it crosses

Findley Ridge on Crown Mountain. It was located in a hollowed-out

area created when top soil was dug out and hauled away for use as

a base for paving the road. According to Madeleine Anthony, who

wrote a feature article about the Findley Ridge Park for the

Gainesville

Times

, the top soil removed was gold ore, making Highway

60 “the only one anywhere with a gold base.”

In

1961, a roadside park was created beside Highway 60 where it crosses

Findley Ridge on Crown Mountain. It was located in a hollowed-out

area created when top soil was dug out and hauled away for use as

a base for paving the road. According to Madeleine Anthony, who

wrote a feature article about the Findley Ridge Park for the

Gainesville

Times

, the top soil removed was gold ore, making Highway

60 “the only one anywhere with a gold base.”

Anthony

related another piece of interesting information. “While hauling

off the gold-ore-top-soil,” she wrote, “workers uncovered

a gold vein only 10 feet from where a tunnel ended. Had the miner,

in 1850, continued his tunnel 10 feet more, he would have felt like

a millionaire overnight.”

For

some years visitors stopped at the roadside park to read the Findley

Ridge Historical Marker and enjoy the scenic view of the town below

with its backdrop of blue-green mountains. Local residents sometimes

took picnic lunches to eat on the concrete tables or had cookouts

on the outdoor grills. While Highway 60 was widened, however, the

small roadside park was destroyed. The Findley Ridge Historical

Marker put up by the Department of Natural Resources was missing

for a number of years but has now been replaced and may be seen

on the right side of the road as motorists reach the summit of Findley

Ridge headed into Dahlonega.

Attempts have been made in recent years to open the

historic site to those interested in viewing the

remaining artifacts, but the costs of making the area

safe and accessible were prohibitive. At this time

the Findley property is privately owned and is not

open to the public.

|

Unique, "EB on Breast"

Unique, "EB on Breast"

Unique, "EB on Breast"

Unique, "EB on Breast"